Many names, one process

Many names, one processPhotochemical machining is known by a number of names including PCM, photo etching, chemical etching, and chemical machining. All of these names describe the same precision metal etching process. We use a stencil, which we call a photo tool, to expose multiple images of the parts on both sides of a sheet of raw material that has been coated with a light sensitive and acid resistant material, called “resist.” After the images of the parts have been developed, and the uncured resist washed away, we etch the metal around the parts by dissolving it in a ferric chloride solution. The resulting parts have no burrs or deformations of the raw material that can occur with other processes such as punching, stamping, and waterjet or laser-cutting.

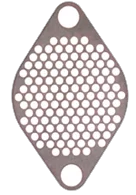

The photo chemical etching process is frequently the process of choice because the tooling is inexpensive and can be produced very quickly, the parts are very precise and consistent, and the metal etching process is particularly effective when the shape of the part is complex and/or the part contains many holes or internal cut-outs.

The photo chemical etching process is frequently the process of choice because the tooling is inexpensive and can be produced very quickly, the parts are very precise and consistent, and the metal etching process is particularly effective when the shape of the part is complex and/or the part contains many holes or internal cut-outs.

Phototools can be rapidly and inexpensively regenerated to accommodate revisions to parts.

You send us data files (dxf, dwg, etc.) so that we can generate the phototools. We can work from paper drawings or sketches.

This link leads to the machine-readable files that are made available in response to the federal Transparency in Coverage Rule and includes negotiated service rates and out-of-network allowed amounts between health plans and healthcare providers. The machine readable files are formatted to allow researchers, regulators, and application developers to more easily access and analyze data.