Contact Us Conard is AS9100D /ISO9001 registered National Quality Associates Certificate 11619 ITAR Registration Number M27542 Download Now Aerospace customers include: Previous Next Photochemical machining is used to produce metal components for many types of aerospace applications from airframe stiffeners…

Contact Us Photo Etching for RF, Microwave and Wireless Technologies Chemical Etching For Communication Technologies Photochemical etching is an economical and productive solution for the many varieties of thin gauge metal parts used for the ever-growing applications in wireless communications….

Contact Us Photo Etched Microelectronics Packaging Photo Etching for Lead Frames and Lids Microelectronics make the world go ‘round. There’s not much left that doesn’t have a semiconductor chip of some sort in it. The semiconductor chip itself is something…

Contact Us Chemical Etching For Medical Devices Technical Sales Professional for Photo Etching Service Instruments and blades in autoclavable stainless steel Filters and sieves for diagnostic and laboratory equipment In-situ targets for imaging applications Closures for incisions Sensor elements for…

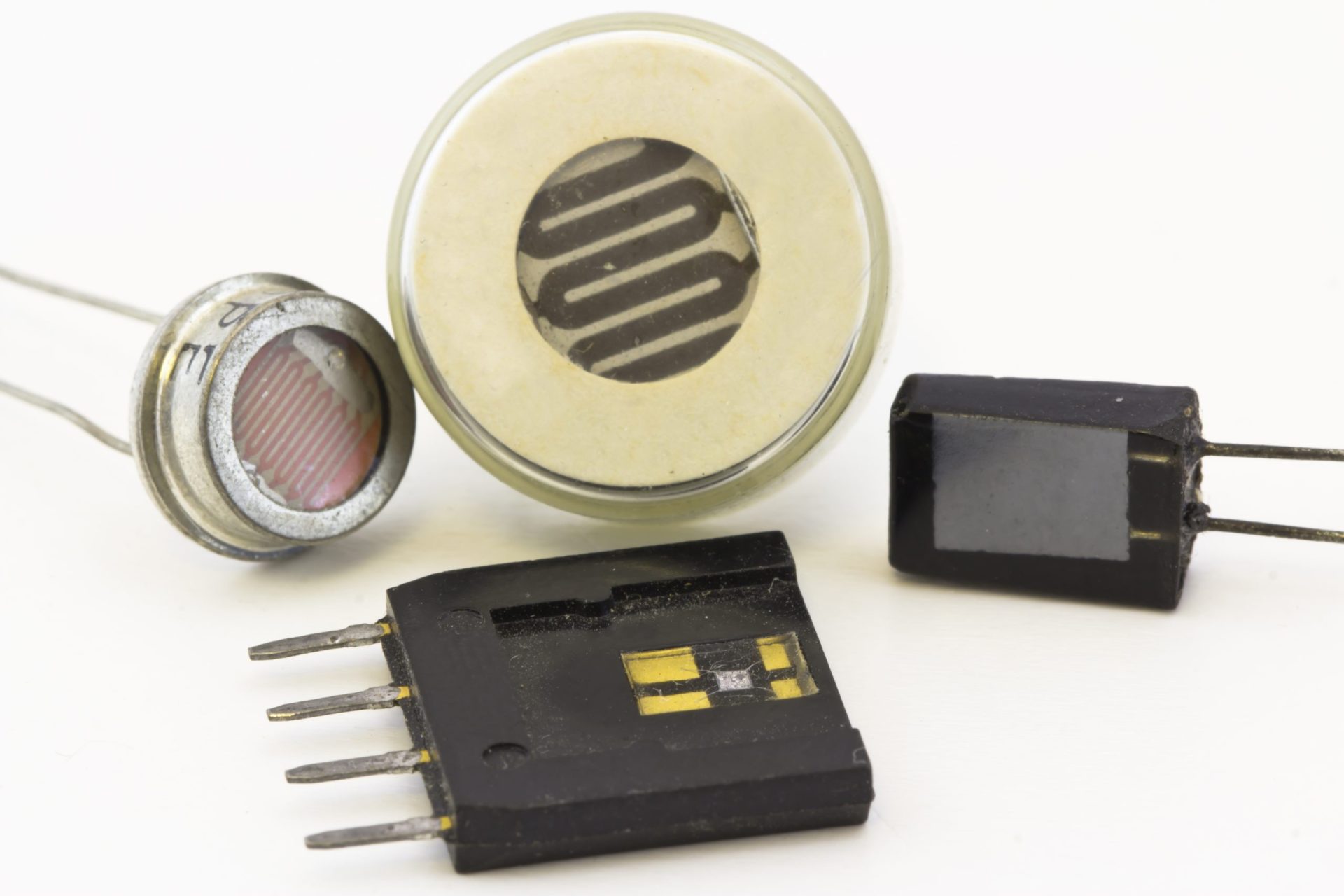

Contact Us Etched Components for Medical, Scientific and Industrial Devices Technical Sales Professional for Photo Etching Service Some of the varied applications for photo etched metal components include: Control and measurement of fluids and gases Air and water analysis Photonics…

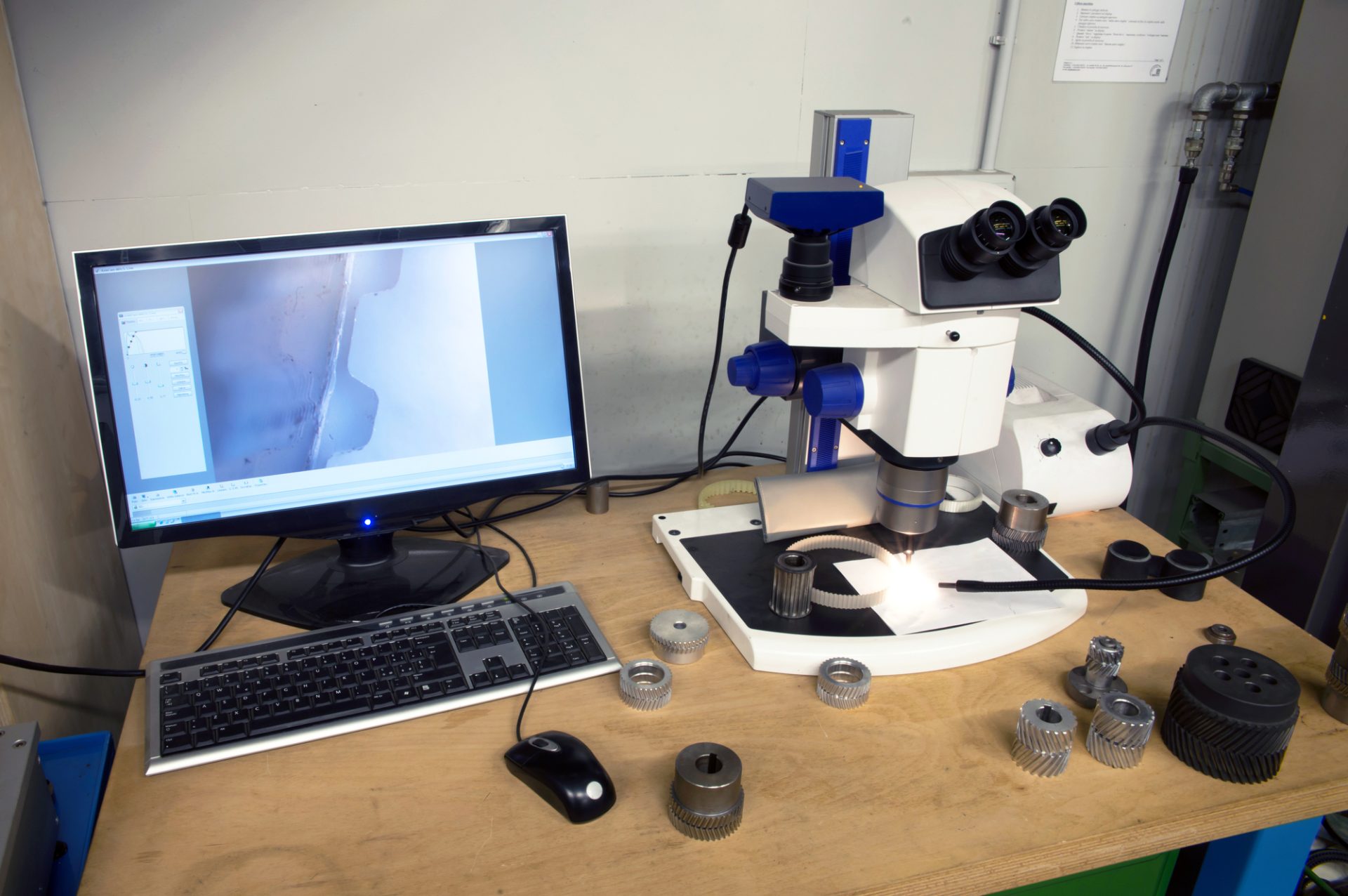

Contact Us Photo Etching for Sensors and Detection Devices Metal Sensors and MEMS Utilize Chemical Etching Photo etching is an effective solution for producing precision parts that are used in sensing, detecting and measuring applications. These types of components interact…

Contact Us Photo Etching for Power Generation and Storage Fuel cells, microturbines and batteries use chemically etched components in a number of ways: proton exchange membranes fuel plates and flow channels heat exchangers air bearings anode grids Renewable energy and…

Contact Us Perforated Metal Chemical Etching Produces Burr-free Holes of Any Shape Holes as small as .004″ (see conditions) Minimum hole size >= to 110% of metal thickness Minimum ligature between holes >= to metal thickness Chemical Etching Paneled Continuous…

This link leads to the machine-readable files that are made available in response to the federal Transparency in Coverage Rule and includes negotiated service rates and out-of-network allowed amounts between health plans and healthcare providers. The machine readable files are formatted to allow researchers, regulators, and application developers to more easily access and analyze data.