The two biggest variables affecting the cost of photo etching are metal thickness and sheet size. Metal thickness bears directly on the length of time it takes to etch through a given metal thickness measured in minutes per mil (.001) of thickness. Sheet size drives the amount of labor that accumulates.

The photo etching process has seven essential steps: cutting, cleaning, laminating, printing, developing, etching and stripping. For each of these steps, a sheet of material must be handled. Each time a sheet is handled into and out of a step in the photo etching process, labor is applied. If you were loading and unloading a pizza oven, your hands wouldnt care if it was a small pizza or a large pizza. You can easily see that loading and unloading many small sheets (pizzas) consumes more labor than handling a smaller number of large sheets.

The effect of sheet size on the cost of photo etching is illustrated in the table below:

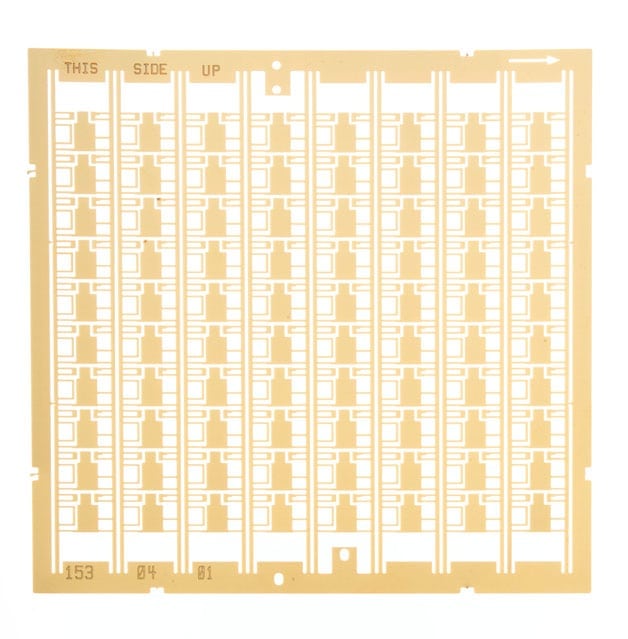

The test part is a 1 x 1 x.010 thick part. It doesnt make any difference whether the part is a simple disk (cheese pizza), a washer (pepperoni pizza), a spring form (pepperoni, sausage and mushrooms), or a screen (the works). The photo etching process doesnt care.

Prices shown do not include any material cost.

| Sheet Size | 12 x 12 | 12 x 18 | 12 x 24 | 18 x 24 |

|---|---|---|---|---|

| Min Tolerance | +/-.002 | +/-.0025 | +/-.003 | +/-.004 |

| 500 | .59 | .43 | .41 | .38 |

| 1000 | .56 | .39 | .36 | .31 |

| 2500 | .52 | .38 | .29 | .25 |

| 5000 | .45 | .33 | .29 | .23 |

| 10000 | .42 | .31 | .27 | .22 |

| 25000 | .40 | .30 |