What is precision photochemical machining?

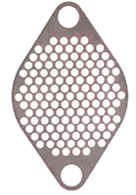

- A means of photofabricating thin gauge precision metal parts

- Metal thickness ranges from .001″ to .080″ depending on the type of metal

- Etchable Metals include many alloys of steel, copper, aluminum, molybdenum and more. More Etchable Alloys

- Alternative to stamping, punching, laser, water jet and wire EDM

- Low cost tooling in one day

- Part sizes from .020″ diameter to 24″ x 60″

- Quantities from handfuls to 100,000s

Photo-Etching vs. Stamping, Laser, Waterjet and Plasma Cutting

Many names, one process

Photochemical machining is known by a number of names including PCM, photo etching, chemical etching, and chemical machining. All of these names describe the same precision metal etching process. We use a stencil, which we call a photo tool, to expose multiple images of the parts on both sides of a sheet of raw material that has been coated with a light sensitive and acid resistant material, called “resist.” After the images of the parts have been developed, and the uncured resist washed away, we etch the metal around the parts by dissolving it in a ferric chloride solution. The resulting parts have no burrs or deformations of the raw material that can occur with other processes such as punching, stamping, and waterjet or laser-cutting.

How Does Etching Compare to Stamping, Laser, Waterjet & Wire EDM?