Etched Surface Features Increase Thermal Capacity

- Component-side heat sinks in aluminum and copper

- Heat exchangers

- Flexible resistive heat elements clad to silicon rubber, polyamide and other insulators

- Three dimensional radiator plates in aluminum

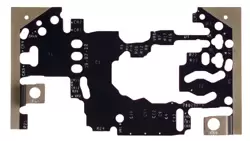

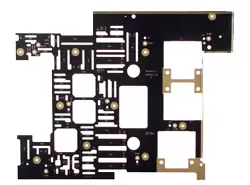

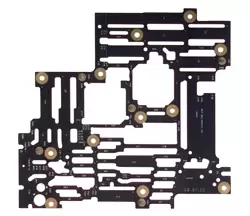

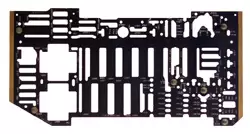

Conard produces photo-etched copper and aluminum circuit board heatsinks for commercial and military applications. Component-side heatsinks are photochemically machined, precision drilled, conversion coated, dielectric epoxy coated and silk-screened. Where required, Conard installs detail parts such as brackets, stiffeners and solder terminals as well.

Our heatsinks and other photo etched parts can be found in electronic engine controls, guidance and navigation systems and environmental systems of military and commercial aircraft, weapon systems, some U.S. Navy ships and NASA’s Space Shuttle fleet.

Photochemical etching is a very effective solution for producing heat transfer and dissipation components that are used in applications including LED lighting, chilling systems, RF and microwave power circuits, as well as printed circuit boards.

Flexible heaters are produced from metal-clad insulating substrates into which the resistor heating element pattern is chemically etched. Resistor element alloys include stainless steel, copper and some nickel-copper alloys. Substrates may be may from rubber, silicone or polyamide materials.